In today’s fast-paced world, industrial environments are louder than ever. Construction sites, factories, manufacturing plants, and even airports are filled with constant noise—much of it dangerous. Workers exposed to prolonged exposure to such high-decibel sounds risk hearing loss, an irreversible condition. The solution? Reusable earplugs.

But the story behind these humble yet essential protective devices is more fascinating than many realize. The history of earplugs—specifically reusable earplugs—intersects with key advancements in safety and personal protection, marking a significant evolution in workplace safety. From ancient methods of sound protection to modern-day industrial ware, earplugs have come a long way.

The Birth of Earplugs: A Journey Through History

Protecting one’s ears from damaging sounds can be traced back to ancient civilizations. The first known use of ear protection comes from the Romans and Greeks, who used ear coverings to block out the sounds of battle or noisy public spaces. These early “earplugs” were often made from materials like beeswax, linen, or cotton, which were shaped and inserted into the ears.

However, it wasn’t until the Industrial Revolution in the 19th century that the need for specialized hearing protection became more pronounced. As factories, steam engines, and machinery started to dominate, workers were subjected to unimaginable noise levels.

By the early 20th century, mass production and urbanization made hearing protection necessary for workers. The first commercially available earplugs were crafted from rubber or flannel, but they were not reusable and far from comfortable. Workers often had to replace them regularly, making them a costly investment for industrial companies.

The Evolution of Reusable Earplugs

Fast-forward to the 1960s, when workplace safety began to receive more attention in industrialized countries. An increased emphasis on worker health and safety followed the establishment of the Occupational Safety and Health Administration (OSHA) in the United States in 1970. More effective and reasonably priced earplugs were introduced due to the growing concern over noise-induced hearing loss.

The invention of foam earplugs in the 1970s was a significant advancement. These were a huge improvement over their predecessors, offering a more comfortable fit and more noise reduction. Although foam earplugs were disposable, workers frequently threw them away after only one usage due to their size and limited lifespan, which added to environmental waste.

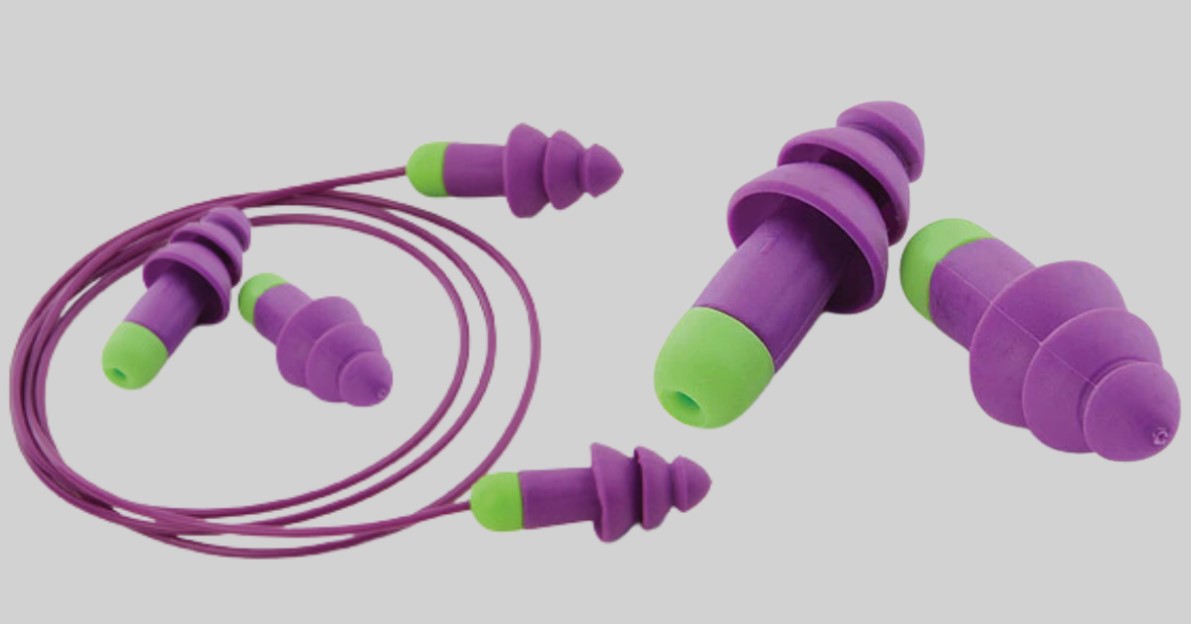

In response to this growing issue, manufacturers turned their attention to reusable earplugs. Unlike their disposable counterparts, reusable earplugs are made from durable materials such as silicone, rubber, or polyurethane, offering long-term protection and a more customized and comfortable fit. These earplugs’ appearance and usefulness have changed over time, adding features like noise-canceling technology, adjustable bands, and even ergonomic forms that fit a range of ear sizes.

The Value of Reusable Earplugs in Industrial Settings

One cannot stress the importance of reusable earplugs for industrial wear. It is not only advised but required to wear hearing protection in areas where noise levels frequently exceed 85 dB, which is the threshold for hearing impairment. The manufacturing, entertainment, mining, and construction sectors depend heavily on high-quality ear protection. One of the most frequent work-related injuries is noise-induced hearing loss, which affects around 22 million American workers annually, according to the CDC.

Why Reusable Earplugs Matter:

Durability and Cost-Effectiveness

One key advantage of reusable earplugs is their cost-effectiveness. While disposable earplugs must be replaced after every use, reusable earplugs can last for months, making them a better investment in the long run. In industries with high numbers of workers, such as construction or manufacturing, reusable earplugs save money over time while providing consistent protection.

Enhanced Comfort and Fit

Unlike disposable earplugs, which often come in standard sizes, reusable earplugs are designed for a more personalized fit. Materials like silicone and rubber conform to the shape of the ear canal, offering superior comfort and reducing the risk of ear irritation. A better fit means higher compliance with safety regulations, as workers are more likely to wear earplugs that feel comfortable for long durations.

Sustainability and Environmental Impact

With growing concerns over environmental sustainability, reusable earplugs offer a solution to the growing problem of plastic waste. By using earplugs that can be cleaned and reused multiple times, industries can significantly reduce the number of single-use earplugs discarded into landfills each year. According to a report by the International Association of Sound and Vibration, the global demand for noise reduction solutions in industrial environments continues to rise, emphasizing the need for eco-friendly alternatives.

Superior Noise Reduction

Reusable earplugs generally offer better noise reduction compared to disposable versions. Whether it’s high-frequency sounds from machinery or low-frequency noise from industrial equipment, reusable earplugs provide a greater range of noise attenuation. Noise reduction ratings (NRR) vary by product, but high-quality reusable earplugs typically offer NRRs of up to 33 decibels, enough to prevent hearing damage in even the noisiest environments.

The Future of Reusable Earplugs: Innovations and Trends

As industries continue to innovate, so too will the design of hearing protection devices. Reusable earplugs are becoming smarter, with advancements in materials that increase comfort, longevity, and protection. Companies are exploring the integration of advanced technologies, such as Bluetooth connectivity, into earplugs for real-time communication and noise management.

Furthermore, the importance of personalized ear protection is on the rise. Custom-molded reusable earplugs that fit the unique shape of an individual’s ear are becoming more popular, providing an even higher level of comfort and effectiveness. These advancements are pushing the boundaries of what hearing protection can offer, ensuring that workers can operate safely without sacrificing comfort or communication.

Conclusion: A Sound Investment for the Future

Reusable earplugs are more than just a safety accessory—they are a crucial part of industrial wear that protects one of our most valuable senses: hearing. From their humble beginnings in ancient civilizations to their modern-day role in preventing hearing loss, reusable earplugs have evolved into an indispensable tool for industrial workers around the world. By investing in high-quality reusable earplugs, industries can ensure the safety and well-being of their workforce while reducing environmental impact and costs.

As noise-related injuries continue to rise, the adoption of reusable earplugs is not just a regulatory necessity, but a step toward a safer, more sustainable future in industrial settings.

Hiking addict, ramen eater, music blogger, Swiss design-head and screen printer. Operating at the fulcrum of design and function to craft meaningful ideas that endure. Check me out on Dribbble or Medium.